In-Mold Decorations: Integrating Layout and Production Quality

In-Mold Decorations: Integrating Layout and Production Quality

Blog Article

Mastering In-Mold Decorations: Approaches, Fads, and Best Practices for Optimum Outcomes

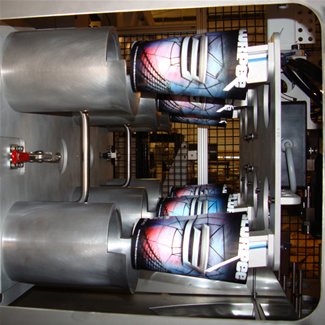

In the realm of manufacturing, the art of in-mold designs stands as a critical facet of product layout and production. As sectors continually look for innovative means to improve aesthetic allure and functionality, understanding the intricacies of in-mold decors has actually emerged as a vital ability set. From choosing the best products to integrating cutting-edge layout patterns, the journey towards accomplishing optimal lead to this domain is diverse. By diving into the methods, fads, and ideal methods that underpin successful in-mold decor processes, services can open a world of possibilities that not just raise the visual allure of their items yet likewise enhance production efficiency and strengthen customer interaction.

Product Option

Material option is an essential aspect of understanding in-mold decorations, as it straight influences the quality and resilience of the final item. When selecting products for in-mold decorations, it is crucial to consider elements such as compatibility with the molding procedure, the desired visual result, and the environmental problems the item will encounter.

Furthermore, the selected material should have good attachment homes to make sure that the decoration adheres securely to the substratum during the molding process. Bond between the decoration and the material is critical for preventing delamination and making certain long-lasting aesthetic appeal. In addition, products with high heat resistance are favored for in-mold designs, specifically for items that will be revealed to elevated temperatures during their lifecycle. By thoroughly selecting the appropriate material for in-mold decors, makers can improve the overall top quality and resilience of their products, satisfying the expectations of both end-users and customers.

Layout Advancement

A vital consider progressing the field of in-mold decorations is the continuous exploration and implementation of style advancement strategies. Style advancement plays an essential role in boosting the visual charm, performance, and overall high quality of products made using in-mold decoration procedures. By incorporating innovative style elements, makers can distinguish their items in the marketplace, bring in consumers, and remain ahead of competitors.

One of the crucial elements of layout advancement in in-mold decorations is the assimilation of elaborate patterns, appearances, and graphics that were previously challenging to attain with conventional design approaches. Advanced modern technologies such as 3D printing and digital style tools make it possible for developers to develop complex and in-depth layouts that can be flawlessly transferred onto shaped components. Additionally, using lively shades, metallic coatings, and special effects like gloss or matte structures can additionally elevate the visual charm of in-mold decorated products.

Furthermore, style development expands beyond looks to incorporate useful enhancements such as ergonomic forms, integrated attributes, and customizable aspects that cater to details user requirements. By accepting style development, producers can open brand-new possibilities for product, imagination, and personalization differentiation in the affordable landscape of in-mold decorations.

Manufacturing Performance

Efficient production processes are vital for translating the innovative designs established in the area of in-mold decors into high-grade completed products that fulfill market needs and consumer expectations. In the realm of in-mold decors, manufacturing efficiency encompasses different key elements that add to the general success of the manufacturing process. One crucial element is the optimization of mold and mildew style and tooling to guarantee smooth and accurate design transfer onto the final product. By fine-tuning mold configurations and buying top quality tooling materials, makers can enhance effectiveness and consistency in production.

Automation not just accelerates the production my company process yet also boosts accuracy and repeatability, leading to an extra top quality and consistent end product. Overall, a holistic approach to production effectiveness is extremely important in taking full advantage of the potential of in-mold decoration techniques and attaining ideal results in the competitive market landscape.

Quality Assurance Actions

What are the crucial methods for making certain rigid top quality control measures in the realm of in-mold decors? Quality control steps are vital in in-mold decor procedures to make certain the manufacturing of top notch and flawless ended up products.

Making use of innovative modern technologies such as automated evaluation systems can additionally boost the top quality control process by offering reliable and precise information for analysis. These systems can spot imperfections that may be missed by manual inspections, thus boosting overall product high quality and uniformity.

Normal training and growth programs for staff members associated with the in-mold decoration procedure can additionally contribute to keeping top quality requirements. By educating staff on finest methods, high quality expectations, and the importance of attention to detail, firms can cultivate a society of top quality consciousness throughout the organization.

Consumer Allure

To improve the bankability of in-mold design items, recognizing and catering to consumer choices play a vital function in identifying their charm and success. Supplying modification options such as customized designs, color variants, and textural elements can dramatically enhance the charm of in-mold decoration items.

Conclusion

In-mold decors offer a effective and versatile way to enhance product visual appeals. By very carefully selecting materials, accepting innovative styles, enhancing production processes, applying top quality control actions, and focusing on customer allure, producers can accomplish optimal outcomes. It is crucial for business to continually adapt and boost their techniques to remain affordable in the market. In-Mold Decorations. More about the author Mastering in-mold decors needs a holistic technique that considers all facets of the manufacturing procedure to make sure success.

In the world of manufacturing, the art of in-mold decors stands as an essential aspect of product design and manufacturing. Layout technology plays an essential duty in boosting the visual appeal, performance, and total top quality of products produced using in-mold decoration processes.One of the crucial elements of design innovation in in-mold decors is the combination of elaborate patterns, appearances, and graphics that were previously challenging to accomplish with standard decoration techniques.Effective manufacturing processes are essential for translating the cutting-edge designs established in the area of Our site in-mold designs right into premium finished products that fulfill market needs and consumer expectations. Supplying modification options such as individualized layouts, shade variations, and textural aspects can dramatically improve the charm of in-mold decor products.

Report this page